Ir Ceramic Board Heaters Manufacturer

Ir Ceramic Board Heater Manufacturer

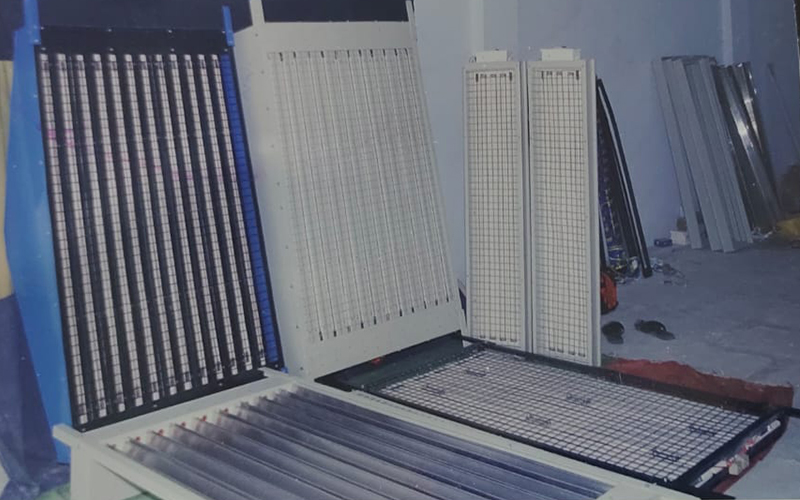

An IR ceramic board heater Manufacturers is a type of electric heater that uses infrared radiation to heat objects or surfaces. It typically consists of a ceramic plate that is heated by an electric current and emits infrared radiation, which is absorbed by the objects or surfaces in the surrounding area. IR ceramic board heaters are often used in industrial and commercial settings, such as in drying or curing processes, or in heating enclosed spaces such as greenhouses. They are also known for their energy efficiency, long lifespan, and fast heating capabilities.

Infrared Ceramic Board Heater manufacturing to textile production, companies utilize heat during their manufacturing processes. This heat often is supplied in the form of convection: a process that works on the easy-to-understand principle of using hot air to heat an object. Another commonly used method is infrared heating. It uses energy in the electromagnetic spectrum to directly provide heat to an object. The principles behind it are somewhat more complex.

Switching from a convection heating system to an infrared system operating at the proper wavelength often is desirable due to the increased efficiency and speed that can be achieved. Consider one example: A company was using a convection system to vulcanize a rubber product. The heating process time was 8 to 10 minutes. After switching to an infrared heating system, the company was able to reduce the heating process time to 3.5 minutes. Effectively, the company doubled its rate of production.

type of Ir Ceramic Board Heater

IR ceramic board heaters are a type of electric heating element that use ceramic as the insulation material and infrared radiation to heat objects or spaces. They are often used in industrial and commercial applications such as heating dryers, ovens, and other equipment. The ceramic material provides high heat resistance and durability, while the infrared radiation allows for efficient and targeted heating. They can be controlled with a thermostat or temperature controller for precise heating.