Textile & Printing Machine Infrared Heater

Textile & Printing Machine Infrared Heater

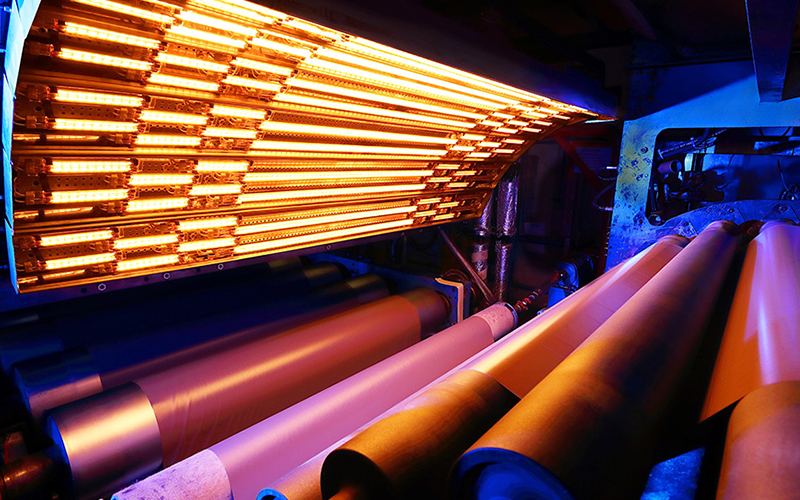

An Textile & Printing Machine Infrared Heater is a type of heater that uses infrared radiation to heat objects and surfaces. In the context of textile and printing machines, infrared heaters may be used to dry ink or other substances on fabric or other materials as they pass through the machine. Infrared heaters are typically more energy efficient than other types of heaters, and they can heat specific areas or surfaces quickly and evenly.

How to Work Textile & Printing Machine Infrared Heater

Textile and printing machine infrared heaters typically use infrared energy to heat up the surface of a material, such as a fabric or paper, in order to dry ink or prepare the material for further processing. The specific operation of an infrared heater will depend on the model and manufacturer, but in general, it may involve the following steps:

1. Turn on the power to the heater and set the desired temperature and timer settings.

2. Place the material to be heated on the heater's surface, making sure it is properly aligned and positioned.

3. Start the heater and monitor the temperature and progress of the heating process.

4. Once the heating process is complete, turn off the heater and remove the material.

It is important to follow the manufacturer's instructions and safety guidelines when operating an infrared heater, as well as to regularly maintain and clean the machine to ensure optimal performance.